Exquisite Craftsmanship

The Naiads' Faucet Manufacturing

Precision Faucet Design and Customization Services

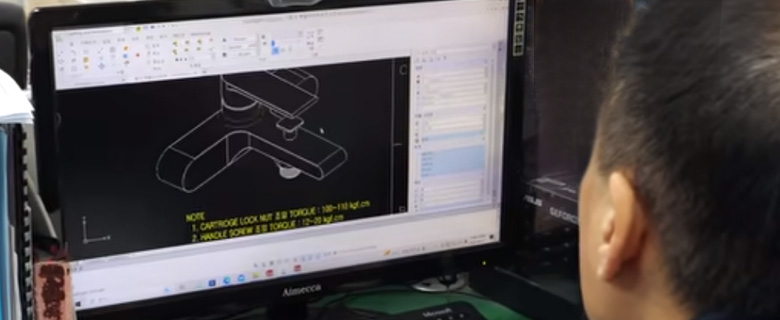

Professional Design and 3D Model Display

The Naiads' experienced design team can provide customized faucet design solutions based on the specific needs of clients. Using CAD software for detailed design planning, we offer 3D models and renderings for each project, ensuring you have an intuitive understanding of the final product.

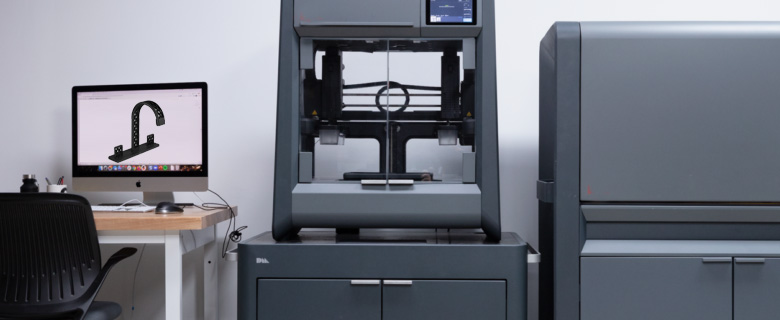

Mold Development and 3D Printing Rapid Prototyping

The Naiads' mold development department is equipped with high-precision CNC machines to ensure the accuracy and durability of faucet molds. With 3D printing technology, clients can receive a rapid prototype of the product within 48 hours, effectively shortening the cycle from design to mass production.

Production Process of High-End Faucets

Mold Design and Production

Our production process starts with mold design, which is customized according to the specific needs of customers. We use advanced CAD software for mold development to ensure mold dimensional accuracy and production efficiency. The mold is made of high-hardness steel to ensure the durability of the mold in large-scale production. The quality of the mold directly affects the dimensional accuracy, surface finish and production efficiency of the final product.

Brass product casting

Our brass products are cast using H59-1 A-grade brass material, which is suitable for products with high strength and corrosion resistance requirements. Through advanced casting technology, we ensure that the brass liquid is cast under a strict temperature control system to ensure the strength and surface finish of the product. We also provide material inspection reports for each batch to ensure that the quality meets customer requirements.

Zinc alloy die casting

We use advanced zinc alloy die casting machines equipped with 400 tons of clamping force, which can produce high-precision zinc alloy products. Real-time monitoring of pressure and temperature during the die casting process ensures that the product has no quality problems such as pores and shrinkage holes.

Injection molding process

Our injection molding machines can produce plastic products with complex structures and high precision. By optimizing mold design and plasticizing temperature control, we can reduce injection time and improve mass production efficiency, which is particularly suitable for large-volume orders.

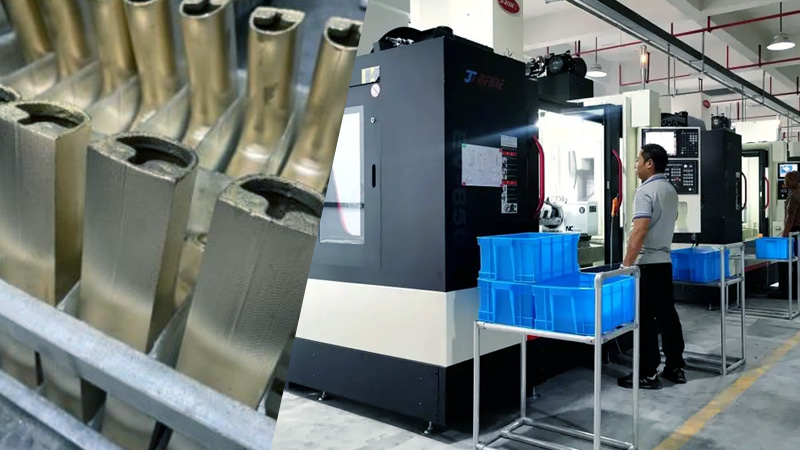

CNC precision machining

After completing the casting and die casting processes, we will use CNC equipment for precision machining. Through CNC technology, we can perform secondary processing on the product to ensure high-precision dimensional requirements and detail processing of complex structures. CNC machining is particularly suitable for complex parts and products with high precision requirements, ensuring that the final product meets the customer's design standards.

Polishing

Polishing is an important process to improve the appearance and texture of the faucet. Through different polishing methods, such as mirror polishing and brushed polishing, the faucet surface presents a highly reflective or matte effect. Mirror polishing makes the faucet surface as smooth as a mirror, which is suitable for modern minimalist bathroom design;Brushed polishing gives the faucet a low-key metallic texture, which is often used in industrial style and classic design products.

The Naiads polishing process can significantly improve the wear resistance and stain resistance of the faucet, so that it remains as new after long-term use.

Surface Treatment Process

Electroplating

The electroplating process is to deposit metal ions on the surface of the faucet through electric current to form a uniform metal coating to improve the product's corrosion resistance and wear resistance.

Electroplating can not only enhance the brightness of the faucet, but also increase its durability. It is widely used in various home and commercial projects. The Naiads offers a variety of electroplating options, including chrome plating, nickel plating, etc., giving the faucet a stylish and modern appearance.

This process is suitable for bathroom products exposed to humid environments for a long time, ensuring that the faucet can remain bright and new even in high humidity environments.

Electrophoresis Coating

Electrophoresis coating is a surface treatment process commonly used for corrosion protection, which can effectively improve the durability of the faucet. The Naiads uses high-performance electrophoresis equipment to evenly adhere the paint to the metal surface of the faucet under the action of an electric field to form a dense anti-corrosion coating.

This coating not only ensures a smooth and uniform surface of the faucet, but also enhances its corrosion resistance, which is particularly suitable for bathroom products that are exposed to humid environments for a long time.

Our electrophoretic coating can ensure that the faucet will not rust or fade for a long time in a high humidity environment.

Powder Coating

Powder coating is a process of spraying plastic powder onto the surface of the faucet through the principle of electrostatic adsorption, and then curing it at high temperature to form a durable coating.

This coating is not only extremely wear-resistant, but also resistant to moisture and corrosion, and is particularly suitable for environments such as bathrooms and kitchens that are often exposed to water.

The Naiads offers a variety of color options to meet the needs of different customers for the appearance of the faucet, such as classic black, metallic gray, etc. The powder coating has excellent adhesion and can ensure that the appearance of the faucet remains bright and new for a long time.

Oil Rubbed Bronze

ORB treatment is a high-end surface treatment process that can give faucets a deep bronze appearance. It is often used for high-end faucets with retro or classic designs.

This process forms a special oxide coating on the metal surface, giving the faucet a unique dark luster and excellent wear resistance.

The Naiads' ORB-treated faucets are visually more heavy and elegant, especially suitable for bathroom designs in luxury homes and high-end hotels.

Brushing

Brushing is a process designed for metal surfaces that can form a uniform texture on the faucet surface, increasing the visual layering and surface wear resistance.

This treatment not only makes the faucet more durable, but also gives the product a low-key and exquisite metal beauty.

The Naiads' brushed faucet surface will not easily leave fingerprints or water stains, suitable for customers who pay attention to the combination of product appearance and functionality.

Spray Painting

The Naiads uses high-quality and environmentally friendly spray painting technology to provide a variety of color and effect options for faucets.

By spraying multiple layers of paint, it can not only add a layer of protection to the faucet, but also give it a variety of appearance effects, such as gloss, matte, metallic luster, etc. The painted faucet is not only full of color, but also has excellent corrosion resistance and wear resistance. It can maintain long-term use without fading or falling off, especially suitable for customized needs in different scenarios such as home and commercial projects.

Physical Vapor Deposition

PVD coating is a high-end physical vapor deposition process that converts the coating material into a gas state in a vacuum and then deposits it onto the surface of the faucet to form an ultra-thin but extremely strong and wear-resistant coating.

The Naiads' PVD process not only gives the faucet a rich color selection, such as gold, rose gold, gun color, etc., but also provides excellent corrosion resistance and wear resistance.This allows the PVD-treated faucet to maintain an elegant appearance in daily use while having long-term durability.

Inspection and Testing Capabilities

Packaging and Logistics

Customized Faucet Packaging Solutions

We provide customized packaging design for each faucet to ensure that the product is not damaged during transportation. Packaging solutions include shockproof, moisture-proof and environmentally friendly materials, suitable for global transportation needs.

International Logistics Cooperation

We cooperate with many international logistics companies to provide fast and safe logistics services. Whether it is bulk cargo shipped by sea or small batch shipments by air, we can ensure on-time delivery.

Supply Chain Management

Sustainable Development

Customer Cases and Reviews

We cooperate with well-known faucet brands in Europe and Asia, providing a full range of high-end faucet products, from design, production to surface treatment and quality testing, to help customers enter the global market and gain wide recognition.

Customer Reviews

At the same time, we provide you with the following services:

1.Provide professional advice on the faucet market

2.Latest product catalog

3.Provide diversified faucet designs

4.Provide product photos and videos

5.Customize exclusive faucets for your brand

6.Product installation manual

- Mobile Phone

- *Title

- *Content